With our best-in-class CAD technology and proprietary formulae, our experienced engineering team can design any marine exhaust or ventilation system to meet your vessel’s exact specifications.

Wet exhaust is the process in which the cooling water is injected into the exhaust line, reducing both the temperature of the gas along with the accompanying fumes. Wet exhaust systems have the advantage of using the heat-absorbing and sound-dampening qualities of water to cool and quiet the exhaust. It also transports raw water or sea water and protects the engine against water entry. Centek Marine offers both propulsion and generator exhaust.

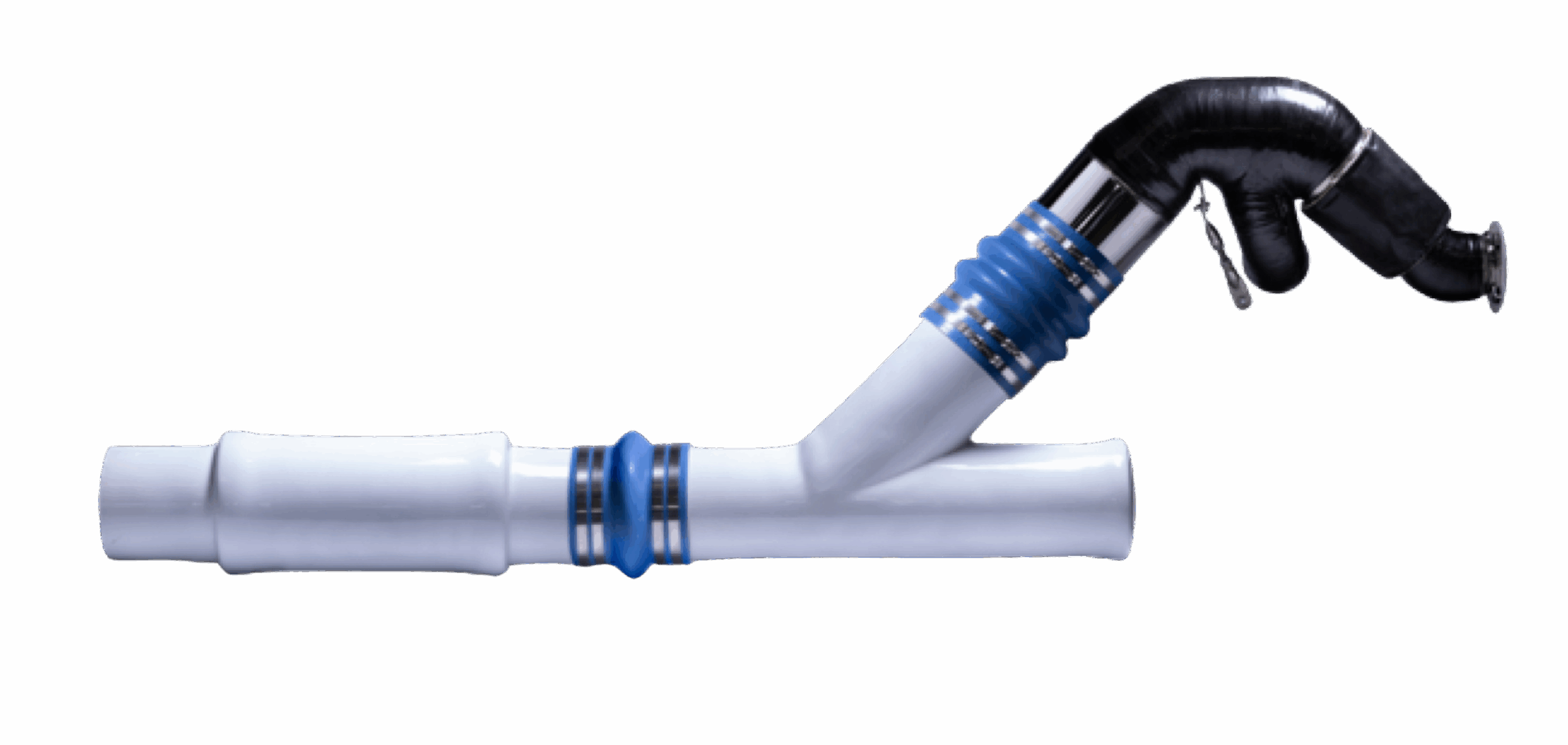

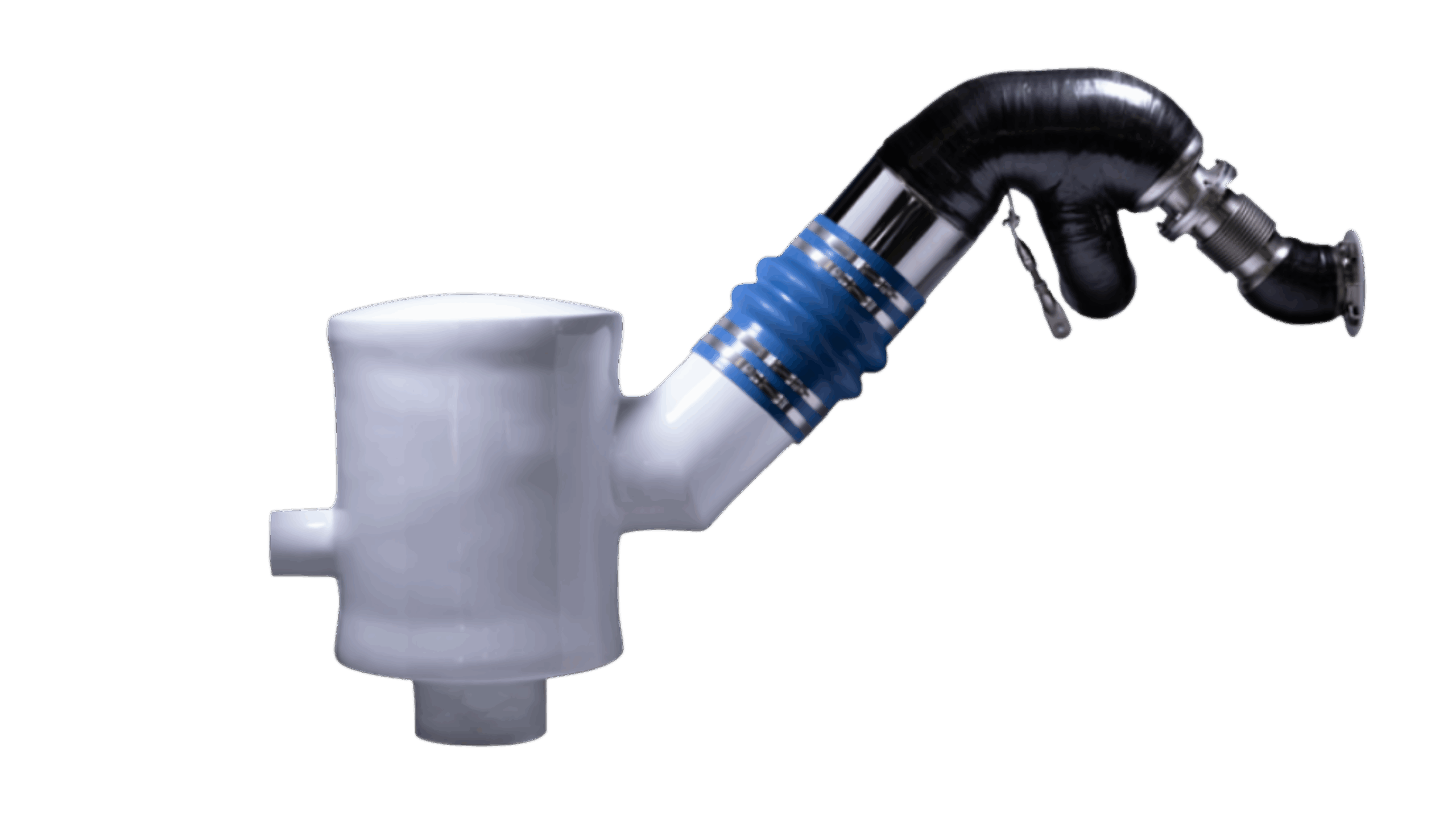

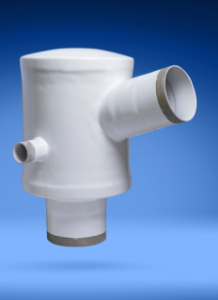

With propulsion exhaust, gases directly from the engine reaching up at 1,000 degrees Fahrenheit are carried in a metal riser and injected with cooling water. The cooled water then goes into a muffler that is specifically engineered to attenuate the sound produced by the engine while balancing backpressure allowances specified by the engine manufacturer.

Centek Marine mufflers are manufactured using fiberglass reinforced plastics (FRP), which will not corrode or deteriorate when exposed to gasoline or diesel fumes mixed with salt or fresh water. Unlike metal applications, rubber, or plastic mufflers, FRP will not warp or melt. Centek Marine Mufflers are available in standard finishes including white and black gel coat and yacht quality — or let us create a custom color or finish for you.

Ventilation systems play several critical roles in an engine room, from airflow to temperature control to the elimination of moisture.

Through its world-class, globally renowned line of Delta-T Systems ventilation products, Centek Marine offers complete engine room ventilation design from inlet to outlet. Our experienced engineering team maintains an extensive database of heat and air requirements from virtually every marine diesel engine and generator manufacturer along with our own calculations and formulae from over 20,000 installations.

Using this information, our expert engineers can design a full ventilation system to meet your vessel’s exact specifications.

Ventilation Control Systems are designed to control intake and exhaust fans in the engine room based on the pressure and/or temperature readings to provide the combustion air needs of the vessel’s engines. There are three different models: the MAC, TAC, and PTAC. The PTAC now can set temperatures in either Fahrenheit or Celsius.

Head Vent Systems provide simple, cost-effective ventilation of the heads or other small spaces onboard a vessel. It provides quiet and efficient air extraction using a single, remotely-located blower to extract stale air from multiple locations.

DC Fan Control Systems are designed to automatically control engine room ventilation via a two-temperature setting while still having the convenience of manual low- and high-speed control. This system design allows for a reduction in noise levels and reduces the current draw by up to 25%.

Office/No. 9, Citi Tower, Sec. 15, CBD Belapur, Navi Mumbai-400614, Maharashtra

Ⓒ Majestis Experts Service. All Right Reserved. Powered by - Integralinfosystems.com